![]()

The αSTEP AZ Series stepper motor offers closed loop control, substantially reduces heat generation from the motor and by incorporating the newly developed Mechanical Absolute Encoder, absolute-type positioning is available, without battery back-up or external sensors to buy. Requires αSTEP AZ Series Driver.

| Items |

/Asset/azm24ak-img-400px.jpg /Asset/azm24ak-img-400px.jpg AZM24AK 1.10 in. (28 mm) AZ Series Stepper Motor with Absolute Mechanical Encoder (DC Input) Web Price $342.00

|

/Asset/azm24ak-img-400px.jpg /Asset/azm24ak-img-400px.jpg AZM26AK 1.10 in. (28 mm) AZ Series Stepper Motor with Absolute Mechanical Encoder (DC Input) Web Price $342.00

|

/Asset/azm24ak-ps-img.jpg /Asset/azm24ak-ps-img.jpg AZM24AK-PS7.2 1.10 in. (28 mm) AZ Series Planetary Gear Stepper Motor with Absolute Mechanical Encoder (Gear Ratio: 7.2:1) (DC Input) Web Price $684.00

|

/Asset/azm24ak-ps-img.jpg /Asset/azm24ak-ps-img.jpg AZM24AK-PS10 1.10 in. (28 mm) AZ Series Planetary Gear Stepper Motor with Absolute Mechanical Encoder (Gear Ratio: 10:1) (DC Input) Web Price $684.00

|

/Asset/azm24ak-hs-img.jpg /Asset/azm24ak-hs-img.jpg AZM24AK-HS50 1.10 in. (28 mm) AZ Series Harmonic Gear Stepper Motor with Absolute Mechanical Encoder (Gear Ratio: 50:1) (DC Input) Web Price $1,043.00

|

|||||

| Frame Size | - 1.1 in28 mm | - 1.1 in28 mm | - 1.1 in28 mm | - 1.1 in28 mm | - 1.18 in30 mm | |||||

| Motor Length | - 2.15 in.54.5 mm | - 2.91 in.74 mm | - 3.13 in.79.5 mm | - 3.13 in.79.5 mm | - 3.11 in.79 mm | |||||

| Driver Voltage Input Power | - DC | |||||||||

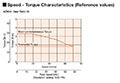

| Speed-Torque Characteristics |

-

|

-

|

-

|

-

|

-

|

|||||

|

Holding Torque |

- 13.4 oz-in0.095 N·m | - 26 oz-in0.19 N·m | - 42 oz-in0.3 N·m | - 71 oz-in0.5 N·m | - 250 oz-in1.8 N·m | |||||

| Shaft/Gear Type | - Round Shaft with Flat (No Gearhead) | - Round Shaft with Flat (No Gearhead) | - Planetary Gear | - Planetary Gear | - Harmonic Gear | |||||

| Gear Ratio (X:1) | - | - | - 7.2 :1 | - 10 :1 | - 50 :1 | |||||

| Backlash | - | - | - 35 arc min (0.59°) | - 35 arc min (0.59°) | - | |||||

| Lost Motion | - | - | - | - | - 1.5 arc min (max.) | |||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Connection Type | - Cable | |||||||||

| Permissible Speed Range (r/min) | - | |||||||||

| Rotor Inertia | - 0.05 oz-in²9.2x10-7 kg·m² | - 0.093 oz-in²17x10-7 kg·m² | - 0.05 oz-in²9.2x10-7 kg·m² | - 0.05 oz-in²9.2x10-7 kg·m² | - 0.066 oz-in²12x10-7 kg·m² | |||||

|

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards |

- CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 10.1 lb0.2 in. from Shaft End = 13.5 lb0.39 in. from Shaft End = 18 lb0.59 in. from Shaft End = 22 lb0 mm from Shaft End = 45 N5 mm from Shaft End = 60 N10 mm from Shaft End = 80 N15 mm from Shaft End = 100 N | - 0 in. from Shaft End = 10.1 lb0.2 in. from Shaft End = 13.5 lb0.39 in. from Shaft End = 18 lb0.59 in. from Shaft End = 22 lb0 mm from Shaft End = 45 N5 mm from Shaft End = 60 N10 mm from Shaft End = 80 N15 mm from Shaft End = 100 N | - 0 in. from Shaft End = 22 lb0.2 in. from Shaft End = 30 lb0.39 in. from Shaft End = 39 lb0.59 in. from Shaft End = 56 lb0 mm from Shaft End = 100 N5 mm from Shaft End = 135 N10 mm from Shaft End = 175 N15 mm from Shaft End = 250 N | |||||

| Permissible Thrust Load | - 1.1 lb5 N | - 1.1 lb5 N | - 8.9 lb40 N | - 8.9 lb40 N | - 31 lb140 N | |||||

| Permissible Thrust Load | - | |||||||||

|

|

||||||||||